Our quality manufacturing policy runs in harmony with our business strategy. Since we only focus on B2B with our business partners locally and internationally, we have built our strategy to guarantee the success of our business partners, which guarantees our own success. This is why, we have invested in the most critical manufacturing processes to improve both quality and cost effectiveness.

General production lines

Our general production lines include PVC compounding and granulation, extrusion machines, mold design and manufacturing, injection machines, assembly lines and clean rooms, and packaging machines and sterilization rooms.

Extrusion machines

Our facilities include 4 different types of extrusion machines for Polyurethanes, PVC, Polyethylene, and more.

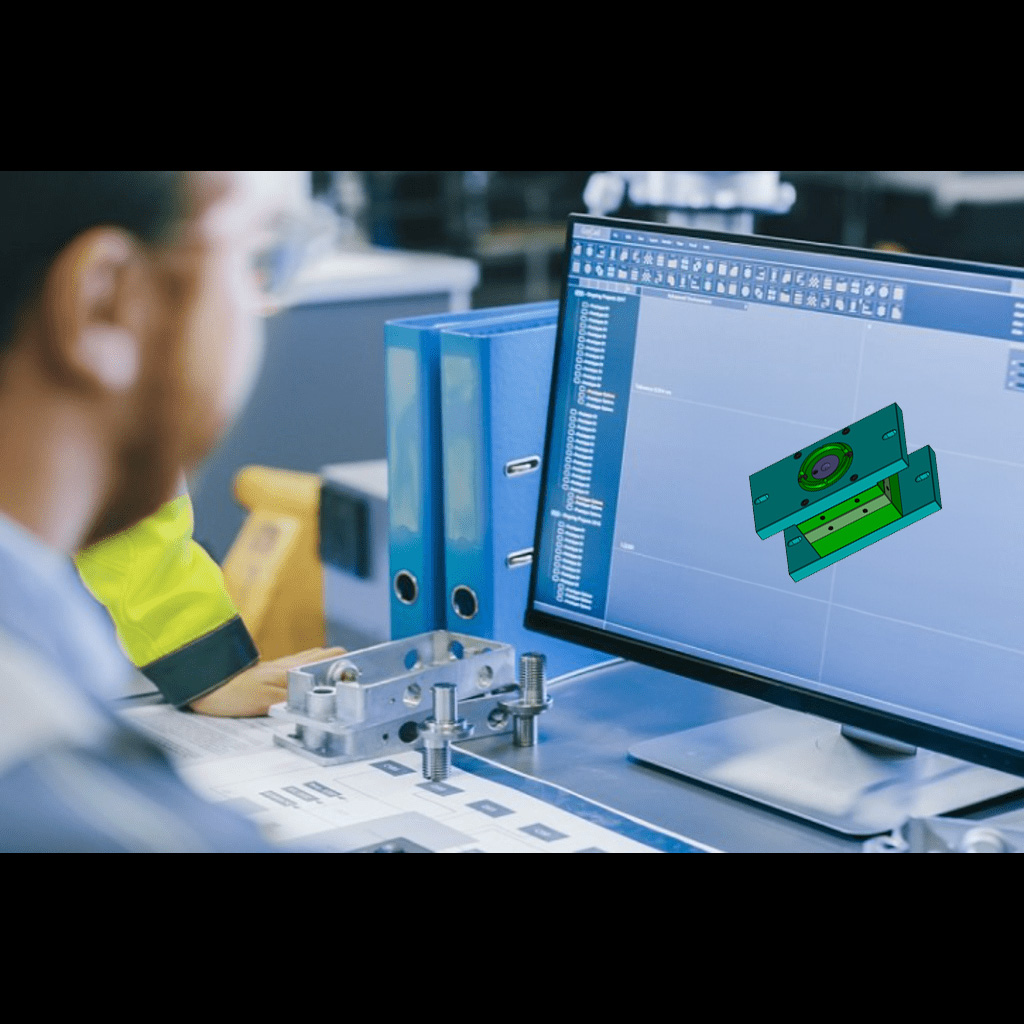

Mold design & manufacturing

At Q Medical we design and manufacture some of our molds using our own CNC machines to produce and maintain molds for greater flexibility and control over our parts.

"We have built our strategy to guarantee the success of our business partners."

Assembly lines

Our assembly lines are distributed over five clean and control halls. State of the art laser machines. Ultrasonic machines with robotic arms. Radiofrequency and thermoforming machines. Quality testing equipment on production lines.

Injection machines

State of the art, highly computerized control injection machines with varying capacities. Specially designed for medical products. We proudly produce all our plastic components.

Clean rooms

We conduct our assembly in our ISO13485:2012 and ISO standard 14644 validated and certified clean rooms. Certified by international and local authorities.

Packaging

Online thermoforming and pouch making machines for inhouse clean production of our own pouch designs and sizes which means greater customization for our customers.

Sterilization

ISO 11135 standard sterilization rooms on premise.

Specialized production lines

Our specialized machinery includes tipping machines, laser and heat controlled automatic punching and drilling machines, 360 degree automatic pad and laser printing machines, overmolding injection machines, state of the art flow and leak online testing, and pouch and tray making and online sealing machines.

Tipping machines

USA made automatic PLC radiofrequency and heat induction tipping machines supported by high precision special material tipping molds.

Punching & drilling machines

Laser and heat controlled automatic punching and drilling machines.

Printing machines

360-degree automatic pad and laser printing machines.

"We have invested in the most critical manufacturing processes to improve both quality and cost effectiveness."

Overmolding Injection machines

Overmolding injection machines inside our clean rooms are supported by USA made molds to provide high precision products and guarantee optimum sterilization conditions.

Leak & flow online testing

Used for 100% of our specialty products to guarantee patient safety.

Pouch & tray making & online sealing machines

State of the art machines inside clean rooms to guarantee complete cleanliness and sterility of our products.